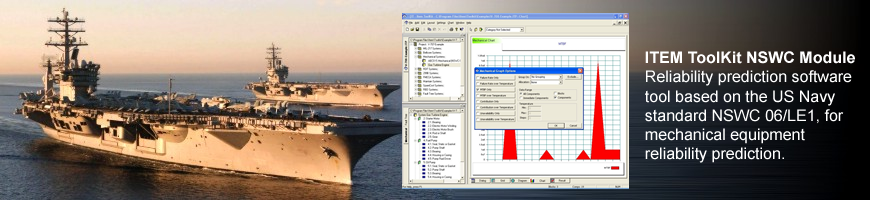

NSWC Module

NSWC Mechanical Reliability Prediction

The NSWC module of ITEM ToolKit uses a series of models for various categories of mechanical components to predict failure rates based on temperature, stresses, flow rates and various other parameters. It provides models for various types of mechanical devices including actuators, springs, bearings, seals, electric motors, compressors, pumps, brakes and clutches and many more. NSWC is currently the only one of its kind.

Due to the wide range of failure rates that occur in apparently similar components, the NSWC Mechanical Prediction module does not rely on failure rate data alone. It also accounts for material properties, operating environment, and critical failure modes at the component level.

The NSWC 11 (98/LE1, 06/LE1) Standard is a commonly used model for mechanical components. Standard procedures for predicting the reliability of mechanical components, sub-systems and systems are defined in the Naval Surface Warfare Center Handbook of Reliability Prediction Procedures for Mechanical Equipment.

The NSWC Handbook

The “Handbook of Reliability Prediction Procedures for Mechanical Equipment” contains twenty-three chapters of information with equations, engineering tables and procedures for estimating the reliability of a mechanical design for the intended operating environment. Handbook procedures are used to determine the reliability of fundamental components such as springs, bearings, seals and gaskets. These component applications are then expanded to sub-assemblies such as valves, actuators and pumps and then to the system level. Equations in the Handbook include parameters for material properties, operating conditions and stress levels at each equipment indenture level providing a full reliability, maintainability and availability analysis at the system, assembly and component indenture levels.

Components

The handbook covers the following types of mechanical components:

- Seals and Gaskets

- Springs

- Solenoids

- Valve Assemblies

- Bearings

- Gears and Splines

- Actuators

- Pumps

- Filters

- Brakes and Clutches

- Compressors

- Electric Motors

- Accumulators

- Threaded Fasteners

- Mechanical Couplings

- Slider-Crank Mechanism

- Sensors and Transducers

- Shafts

- Belt Drives

- Fluid Conductors

- Miscellaneous Parts

Features

- Powerful and user friendly NSWC 11 mechanical reliability prediction software

- Also includes NSWC 98/LE1 and 06/LE10 standards

- Linked Block facility reduces repetitive data entry

- Redundancy modeling including hot standby

- Multi systems within the same project

- Extensive component libraries to reduce entry time

- Multi-document interface allows easy transfer of data

- Powerful charting facilities

- Combine prediction methods for complex analysis

- Optimize designs to meet targeted goals

- Select components with regard to reliability and cost savings

ITEM ToolKit’s Reliability Prediction Modules

ITEM ToolKit contains six modules for performing reliability prediction (MTBF) analysis. These modules conform to MIL-HDBK-217 F Notice 2, Telcordia (Bellcore) TR-332 and SR-332, IEC 62380 (RDF 2000), IEC 61709, China 299B GJB/z 299B (electronics) and NSWC 06 (mechanical) and share many common features and capabilities.

Each reliability prediction module is designed to analyse and calculate component, sub system and system failure rates, including Mean Time Between Failure (MTBF), in accordance with the appropriate standard. After the analysis is complete, ITEM ToolKit’s integrated environment comes into its own with powerful conversion facilities for transferring data to other modules of the program. For example, transfer your MIL-217 project data to FMECA or your Telcordia project to RBD. These powerful facilities transfer as much of the available information as possible, saving you valuable time and effort.

ITEM ToolKit’s Multi Document Interface allows several projects or libraries to open at the same time. This valuable feature comes in especially handy when it is necessary to transfer data from one project (or library) to another.

Users can construct hierarchical breakdowns of systems with no restrictions on block numbers or levels of indenture. As new sub blocks and components are added, ITEM ToolKit automatically recalculates all dependent failure rates to take account of new information.

Powerful global editing facilities are available for performing “what if” evaluations. These facilities enable you to experiment with temperature, environmental and stress settings and see how your system performance will vary.

Contact us now for a free quotation or an online demonstration.

- Mechanical Reliability Prediction Software

- US Navy Standard NSWC 98/LE1

- US Navy Standard NSWC 06/LE10

- US Navy Standard NSWC 11

- Mean Time Between Failure Calculation

- User Defined Custom Libraries

- One of Thirteen ITEM ToolKit Modules

- Extensive Reporting and Charting Facilities

ITEM ToolKit Modules:

- MIL-HDBK-217 Prediction >>

- Telcordia Module >>

- IEC 62380 Prediction >>

- IEC 61709 Prediction >>

- NSWC Mechanical Prediction >>

- China 299B Prediction >>

- Failure Mode, Effects, and Criticality Analysis >>

- Reliability Block Diagram >>

- Fault Tree Analysis >>

- Event Tree Analysis >>

- Markov Analysis >>

- Maintainability >>

- Spares Scaling & Ranging >>