IEC-61709 Module

IEC 61709 Electronic Reliability Prediction

The IEC-61709 module supports the reliability prediction methods based on the European Prediction Standard IEC-61709. This module is predominantly based on the Siemens Prediction Standard SN-29500, as well as conforming to section 19 for PCBs and section 20 for the Hybrid Circuits within the European Prediction Standard IEC-62380 (RDF 2000/UTE C 80-810).

The IEC-61709 module provides models for reliability prediction of electronic components, printed circuit board and equipment extrapolated of failure rates from referenced conditions to other operating conditions that permits the prediction of failure rates at assembly level.

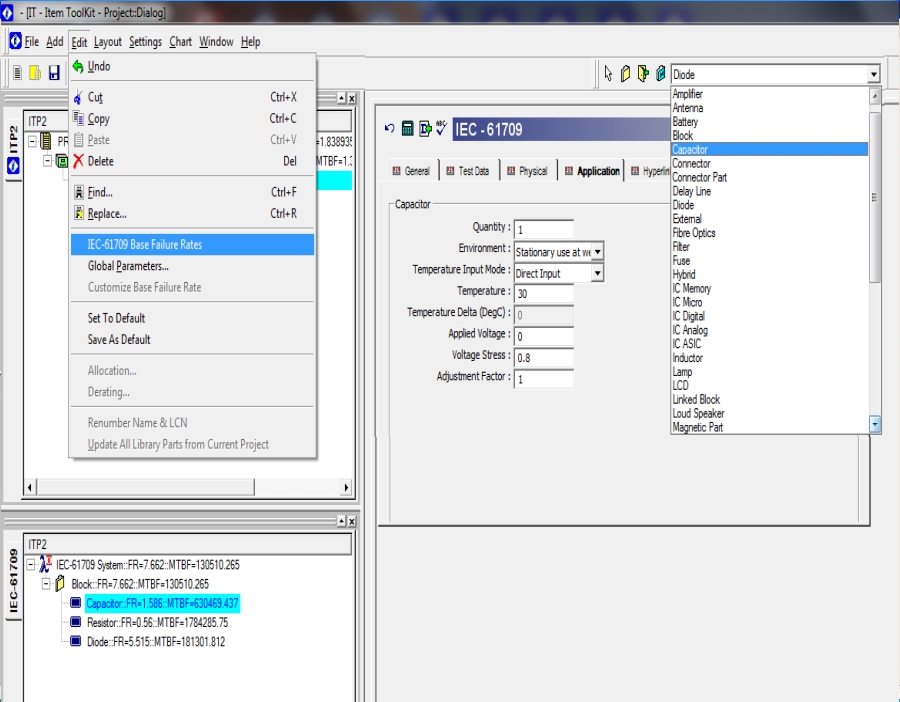

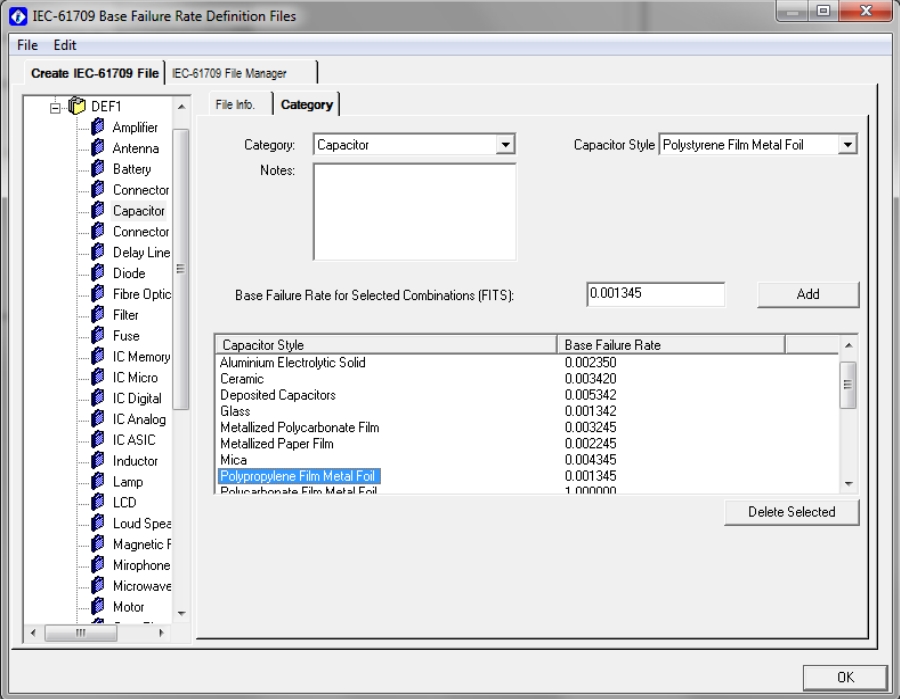

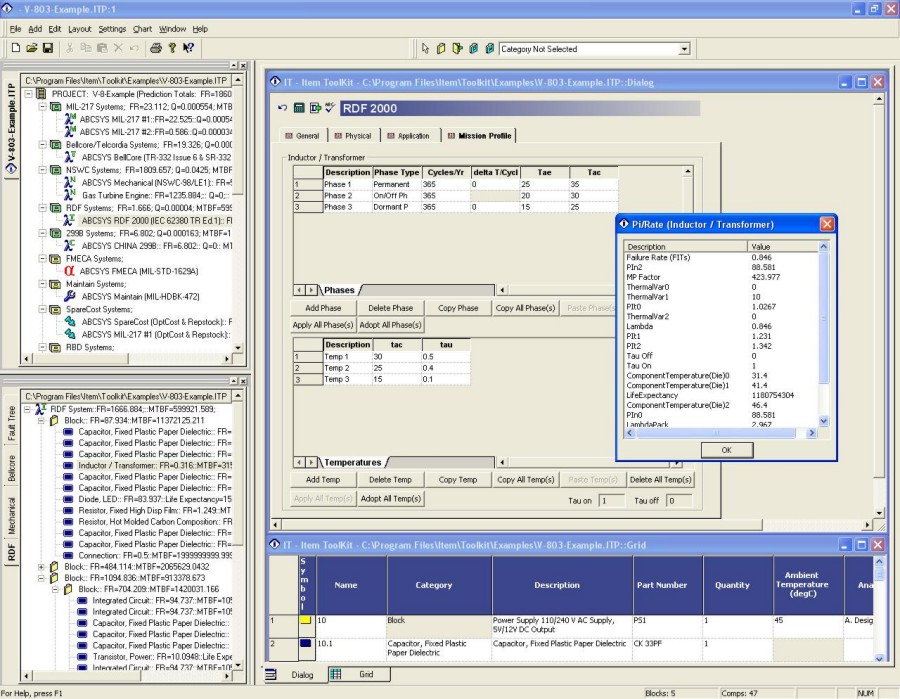

ITEM ToolKit platform offers the linking of source failure rate data to and from other prediction modules as well as having powerful import/export capabilities. The IEC-61709 module can be used to obtain failure data from other ToolKit prediction modules as well as sourced failure rates, either direct from the component manufacturers or organisations who have failure rate databases that contain collected field reliability data. This data will provide the base failure rate for the ITEM ToolKit IEC-61709 module, which along with the user defined application parameters specified in the IEC-61709 standard, would provide the complete reliability prediction analysis based on the IEC-61709 module.

Library management, import and export facilities are also provided. Quality user-configurable reports are produced by the program automatically. In addition, data may simply be dragged and dropped into Microsoft applications such as Word, Excel, Access etc. allowing a wide range of additional customised reports and charts to be produced.

Features

- Powerful and user friendly IEC-61709 electronic reliability prediction software

- Combine prediction methods for complex analysis

- Drag and drop components and systems between projects

- Mean Time Between Failure (MTBF) calculation

- Powerful charting facilities

- User defined custom library facilities

- Build and open multiple systems and projects files

- Import and export to MS Excel, Access and Word etc.

- Select components with regard to reliability and cost savings

- Multi Systems within the same project

- Transfer to and from any other module

- Linked Blocks, represent blocks with identical characteristics

- Optimize designs to meet targeted goals

- Redundancy modeling including hot standby

- Take advantage of powerful ‘what if’ analytical tools

- Identify weak areas in a system design

ITEM ToolKit’s Reliability Prediction Modules

ITEM ToolKit contains six modules for performing reliability prediction (MTBF) analysis. These modules conform to MIL-HDBK-217 F Notice 2, Telcordia (Bellcore) TR-332 and SR-332, IEC 62380 (RDF 2000), IEC 61709, China 299B GJB/z 299B (electronics) and NSWC 06 (mechanical) and share many common features and capabilities.

Each reliability prediction module is designed to analyse and calculate component, sub system and system failure rates, including Mean Time Between Failure (MTBF), in accordance with the appropriate standard. After the analysis is complete, ITEM ToolKit’s integrated environment comes into its own with powerful conversion facilities for transferring data to other modules of the program. For example, transfer your MIL-217 project data to FMECA or your Telcordia project to RBD. These powerful facilities transfer as much of the available information as possible, saving you valuable time and effort.

ITEM ToolKit’s Multi Document Interface allows several projects or libraries to open at the same time. This valuable feature comes in especially handy when it is necessary to transfer data from one project (or library) to another.

Users can construct hierarchical breakdowns of systems with no restrictions on block numbers or levels of indenture. As new sub blocks and components are added, ITEM ToolKit automatically recalculates all dependent failure rates to take account of new information.

Powerful global editing facilities are available for performing “what if” evaluations. These facilities enable you to experiment with temperature, environmental and stress settings and see how your system performance will vary.

IEC 61709 Reference Documents

The following referenced documents are indispensable for the application of this method. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

- IEC 60050-151:2001, International Electrotechnical Vocabulary – Part 151: Electrical and magnetic devices

- IEC 60050-521:2002, International Electrotechnical Vocabulary – Part 521: Semiconductor devices and integrated circuits

- IEC 60300-3-2:2004, Dependability management – Part 3-2: Application guide – Collection of dependability data from the field

- IEC 60300-3-5, Dependability management – Part 3-5: Application guide – Reliability test conditions and statistical test principles

- IEC 60300-3-9, Dependability management – Part 3: Application guide – Section 9: Risk analysis of technological systems

- IEC 60721 (all parts), Classification of environmental conditions

- IEC 60747-1:2006, Semiconductor devices – Part 1: General

- IEC 61163-2, Reliability stress screening – Part 2: Electronic components

- IEC 61360 (all parts), Standard data element types with associated classification scheme for electric components

- IEC 61360-1:2009, Standard data elements types with associated classification scheme for electric items – Part 1: Definitions – Principles and methods

- IEC 61360-4:2005, Standard data element types with associated classification scheme for electric components – Part 4: IEC reference collection of standard data element types and component classes

- IEC 61649:2008, Weibull analysis

- IEC 61703, Mathematical expressions for reliability, availability, maintainability and maintenance support terms

- IEC 62380, Equipment reliability – Reliability assessment methods

- ISO 10303-11:1994, Industrial automation systems and integration – Product data representation and exchange – Part 11: Description methods – The EXPRESS language reference manual

- ISO 10303-31, Industrial automation systems and integration – Product data representation and exchange – Part 31: Conformance testing methodology and framework: General concepts

- ISO 13584 (all parts), Industrial automation systems and integration – Parts library

- Joint Electron Device Engineering Council(s) (JEDEC), JESD85, Methods for calculating failure rates in units of FITS

- DEF00-42-3, Ministry of Defence Standard 0042 – Reliability and Maintainability (R&M) Assurance Guidance – Part 3: R&M Case

Contact us now for a free quotation or an online demonstration.

- Electronic Reliability Prediction Software

- IEC-61709 Standard

- Mean Time Between Failure Calculation

- One of Thirteen ITEM ToolKit Modules

- Extensive Reporting and Charting Facilities

- Advanced Hybrid Linking and Modeling

- Redundancy Modelling Including Hot Standby

- User Defined Custom Libraries

ITEM ToolKit Modules:

- MIL-HDBK-217 Prediction >>

- Telcordia Module >>

- IEC 62380 Prediction >>

- IEC 61709 Prediction >>

- NSWC Mechanical Prediction >>

- China 299B Prediction >>

- Failure Mode, Effects, and Criticality Analysis >>

- Reliability Block Diagram >>

- Fault Tree Analysis >>

- Event Tree Analysis >>

- Markov Analysis >>

- Maintainability >>

- Spares Scaling & Ranging >>