FMECA Module

Failure Mode, Effects and Criticality Analysis

Not being able to identify your design flaws, failures in manufacturing or processes could result in costly repairs, warranty costs, production delays, catastrophic failures, and even loss of life.

Organizations perform Root Cause Analysis to identify and eliminate severe malfunction and potential failures from products and production processes. An inductive approach or procedure often serves as a design aid to identify and prevent catastrophic failures. The need to determine the effect of system and equipment failure becomes more evident and urgent.

FMECA (Failure Mode, Effects, and Criticality Analysis) analyzes potential failure within a system, identifies the potential hazards associated with these failures, and classifies them according to their severity. FMECA addresses reliability and quality problems associated with design, manufacturing, process, safety, and environment.

Supported Standards

There are many published approaches to performing a FMECA. ITEM ToolKit supports the following:

- MIL-STD-1629a

- IEC-61508 FMEDA

- ISO9000/QS9000

- ISO 26262

- BS 5760 Part 5

- SAE ARP4761

- SAE ARP5580

- SAE J1739

The use of the FMECA module is not limited to these standards however. Your specific FMECA needs can easily be modeled.

Two-Part Analysis

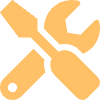

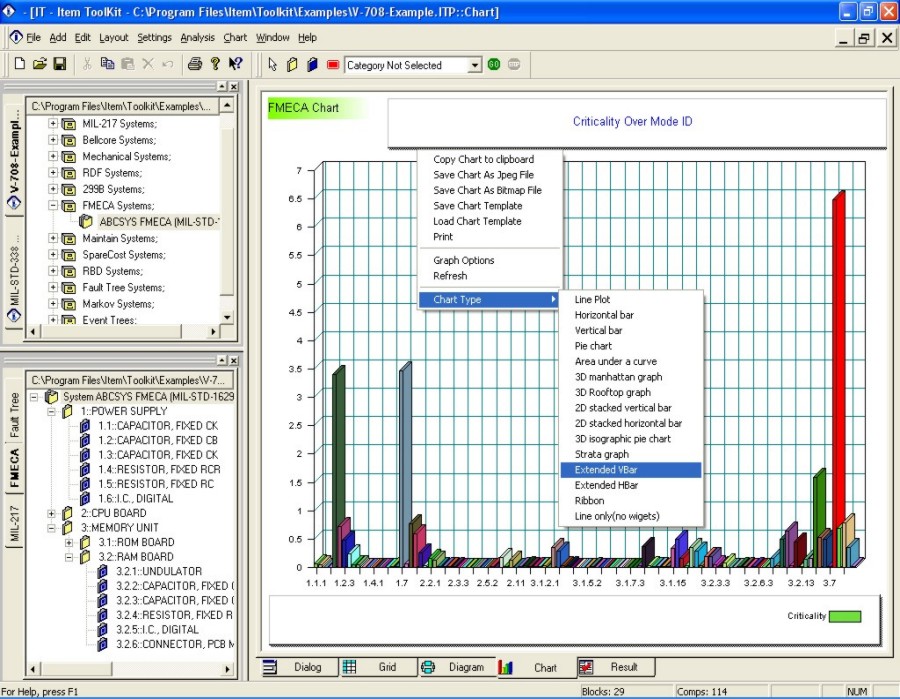

During a FMECA procedure, identifying the failure modes and their effects (Failure Mode Effect Analysis) is often only the beginning. Criticality Analysis is where the failure modes are ranked according to a combination of severity and the probability of that failure mode actually occurring. ITEM ToolKit provides total flexibility for applying FMECA to the two-part analysis and much more.

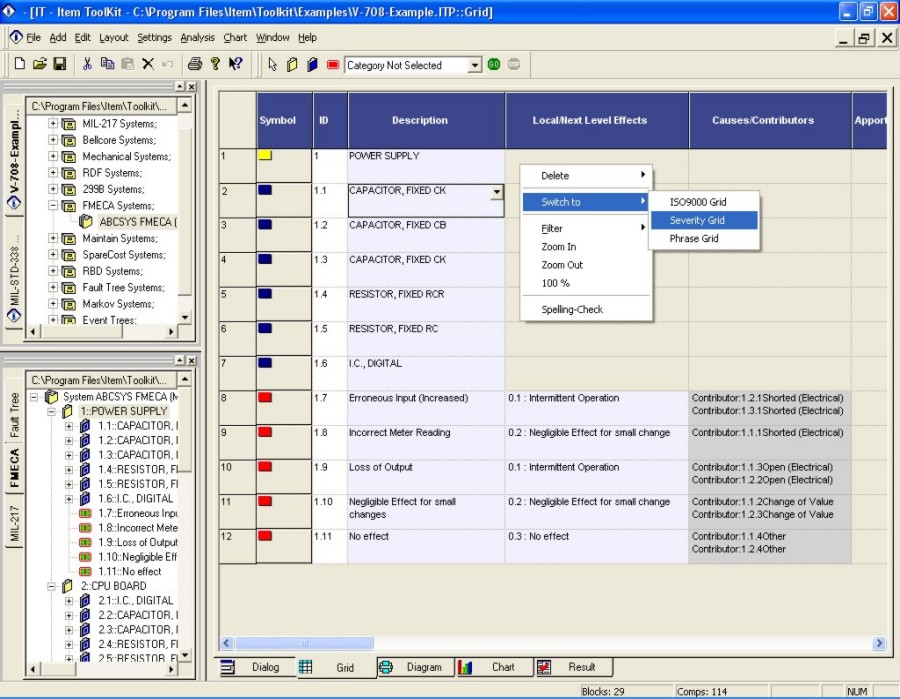

The ITEM ToolKit FMECA module provides an intuitive graphical interface with multiple options for constructing and performing an analysis. With an enhanced hierarchy tree and tabular views designed for user-friendly navigation, data entry and modification have never been easier. The FMECA module provides a coherent, comprehensive method for entering data.

The FMECA Module also provides a phrase library facility containing commonly used descriptions of component parts, failure modes and effects. These greatly speed up data entry and have the added benefit of keeping common phrases consistent. Phrases in this library may be customized to suit your own requirements.

The FMECA Module also includes a failure mode and apportionment library, derived from MIL-HDBK-338, which allows you to create commonly used component and failure mode groupings. The apportionment library can either be used when manually creating FMECAs or to automatically create failure modes and apportionments when transferring data from ITEM ToolKit’s Prediction modules. This capability can dramatically reduce analysis times making you more productive.

The FMECA Module now incorporates a fully integrated IEC 61508 FMEDA analysis. An IEC 61508 conforming quantitative FMEDA (Failure Mode, Effects and Diagnostics Analysis) is only a few mouse clicks away.

Features

ITEM ToolKit FMECA software provides unique features that allow you to quickly and accurately perform your Failure Mode, Effects, and Criticality Analysis, data management, reporting, analytical facilities and much more.

- FMECA software assigns Risk Priority Numbers as needed

- Graphically constructed system hierarchy diagrams

- User-definable data fields and sort facilities

- Failure Effects & Severities traced through to system hierarchy

- Automatically assigned severity values

- User-definable severity category and Matrix

- Automatic criticality calculations

- Multiple failure effects permitted for a single failure mode

- Effects may be defined on any higher-level sub-system

- Libraries of components with predefined modes and apportionment

- Optimization of design to meet acceptable failure modes and severity

- Assignment of IEC “dangerous” versus “safe” at the functional End Effects level

- Regressional top down analysis assigning safe vs. dangerous severity to root modes

- Evaluation of multiple severity assignment by a “split and hit” algorithm

- Independent IEC analysis algorithm for the functional end effects of the FMEDA

- Hardware oriented component level DC and SFF

- Automatic calculation of lambda-SU, SD, DU and DD per each root mode

- Consideration of non propagating root modes in component DC and SFF

- Cut set analysis at each intermediate nodal point of the FMEDA

- Automatic transfer from FMEDA to FTA with failure model and inspection interval

- End-effect trace down to root causes

- Automatic calculation of lambda-Su, lambda-SD, lambda-DU and lambda-DD, per each root mode

- Hardware oriented component level Detectability Coverage and Safe Failure Fraction

- Evalutaion of multiple severity assignment by a ‘split by hit’ algorithm

- Assignment of IEC ‘dangerous’ versus ‘safe’ at the functional end effects level

- Optimization of design to meet acceptable failure modes and severity

Contact us now for a free quotation or an online demonstration.

- FMECA Software

- Supports ISO 26262

- Supports IEC 61508 FMEDA

- Phrase and Failure Mode Facilities

- Apportionment Library Facilities

- Automatic Criticality Calculations

- Graphical System Hierarchy Diagrams

- One of Thirteen ITEM ToolKit Modules

- Extensive Reporting and Charting Facilities

ITEM ToolKit Modules:

- MIL-HDBK-217 Prediction >>

- Telcordia Module >>

- IEC 62380 Prediction >>

- IEC 61709 Prediction >>

- NSWC Mechanical Prediction >>

- China 299B Prediction >>

- Failure Mode, Effects, and Criticality Analysis >>

- Reliability Block Diagram >>

- Fault Tree Analysis >>

- Event Tree Analysis >>

- Markov Analysis >>

- Maintainability >>

- Spares Scaling & Ranging >>