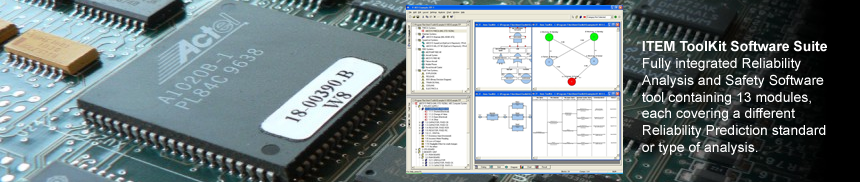

ITEM ToolKit Software

Fully Integrated Reliability Analysis and Safety Software

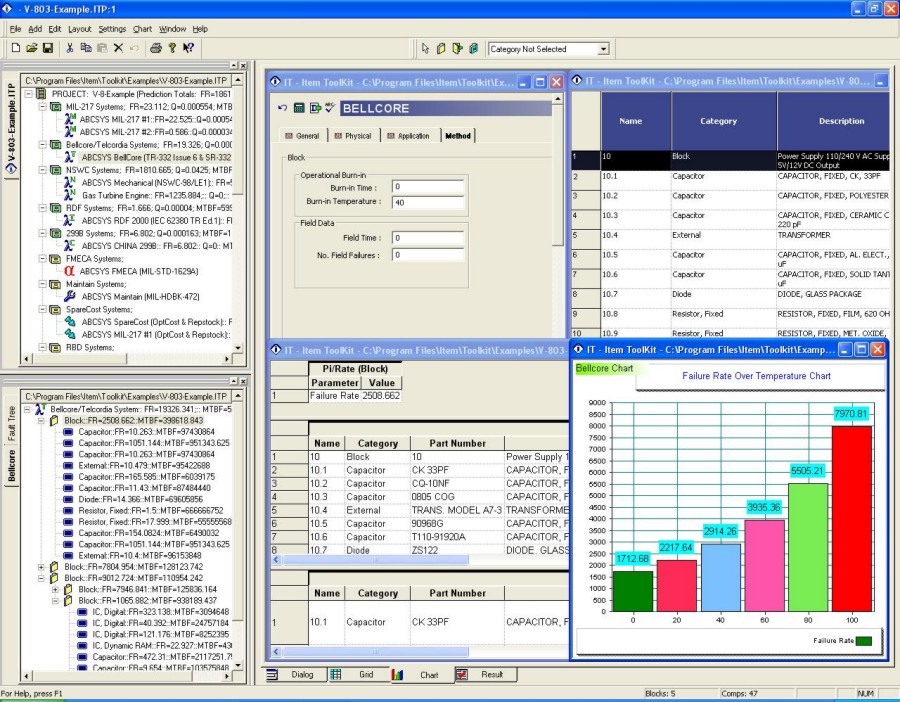

Reliability Analysis Software, ITEM ToolKit is a suite of comprehensive prediction and analytical modules in one integrated environment. ToolKit is an integrated environment benefiting from object-oriented architecture that delivers Accuracy, Flexibility and Ease of Use. It offers you convenient features that provide a consistent format for all your analyses. This enables learning carry-over from one module to another.

ITEM ToolKit has standardized many critical functions, shortcuts, and other features that operate identically in each module to save time and effort, increasing your productivity. Whether you are starting a new analysis or using different modules, the essential functions remain the same. In addition to the standard features, each module functions independently (or linked with others), having its own unique features and functionality.

ITEM ToolKit uses globally recognized standards and methodologies to analyze components, systems, and projects. It allows you to take a total system approach in analyzing individual systems and components. This allows you to optimize your design targets with respect to component selection, increased safety, and reduced liability.

No other reliability analysis tool offers the diverse User Interface as ITEM ToolKit. You can create and analyze multiple systems and projects at the same time, share project files and libraries with other engineers, or departments.

- Build and open multiple systems and project files

- Build several systems at the same time and compare analysis results

- Drag and drop components and systems between projects.

- Create a new project quickly by reusing components from other projects

You can analyze Reliability, Availability, Maintainability, Safety and Risk of components or systems and view the entire project.

Flexible, Easy-to-Use Interface, Viewing and Editing

ITEM ToolKit ‘s easy-to-use User Interface makes it faster and easier to manoeuvre throughout your project or system. You can view your Project or System information in a tabular grid, dialog box, hierarchy tree, chart or graph. You can also control the size and position of any window with standard Windows functions.

New Project or System data can be added via the hierarchy tree, dialog box, or in tabular grid. Editing is as simple as a click on any of the standard options such as Cut, Copy, Paste, and Drag and Drop.

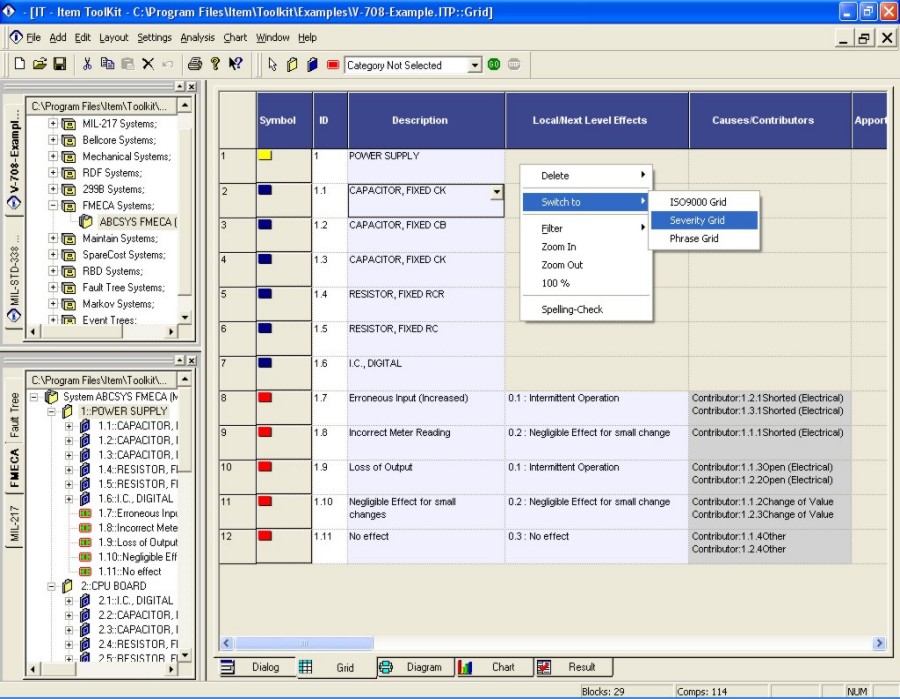

Advanced Grid / Tabular View:

You can add, edit and display the system information and structure in a Grid or “spreadsheet” view. Using filters and adding additional columns, you can customize this view to represent your system as you wish. Use this table as a report by simply dragging the table to Microsoft Excel and share your analysis information with others.

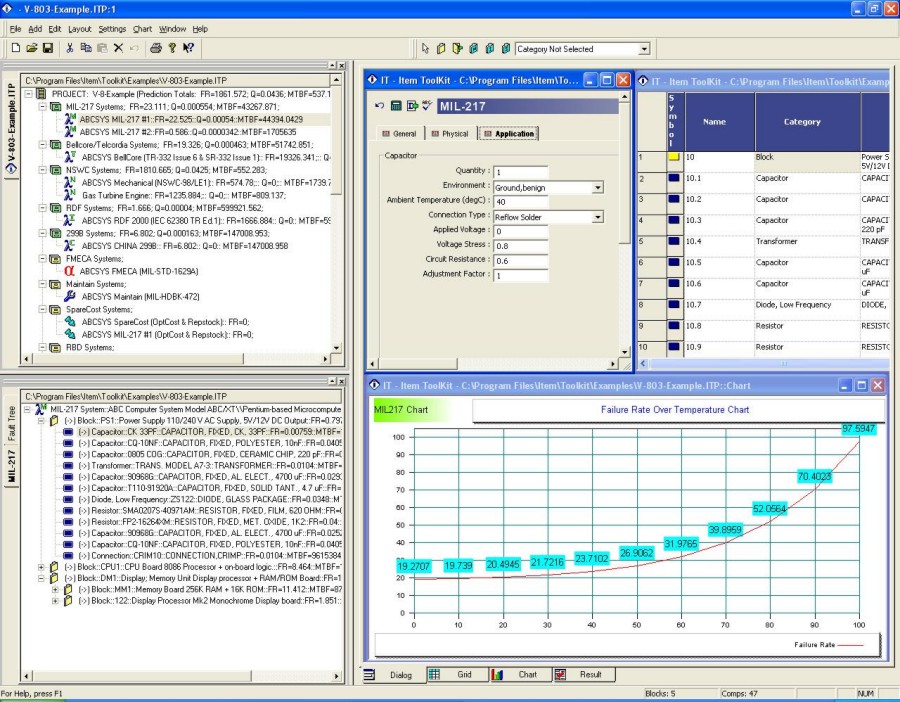

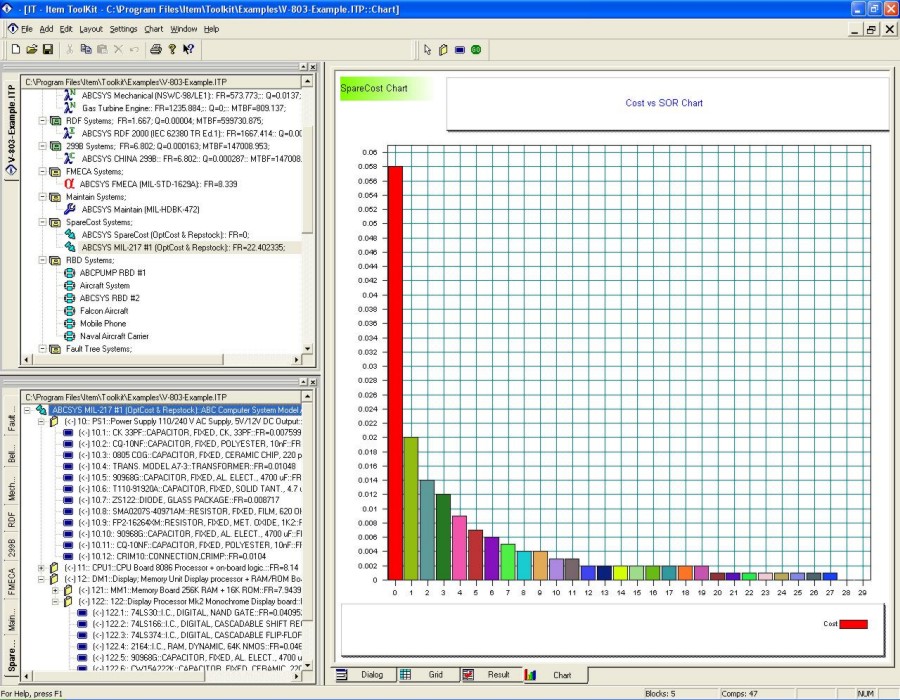

Powerful Chart and Graph Wizard:

ITEM ToolKit offers wide variety of charts and graphs for viewing systems and project data in a graph / chart format. You can choose to generate the charts automatically within ITEM ToolKit , or by using the Chart Wizard and Edit Graph functions, generating custom style charts. You can also save chart displays as image files for use in reports, presentations, etc.

User Defined Custom Libraries

Analyze your system once and create multiple, custom libraries containing components and block information, failure modes, cause and effects, events and fault trees. ITEM ToolKit allows you to create and use multiple libraries at the same time. This time saving feature will shorten the time for constructing new systems. The analyzed components, events or blocks can simply be added to a new system by using the drag-and drop or copy and paste feature. Importing data into ToolKit can also refer to the libraries to draw data from them, reducing the amount of information needed in the import source.

Import/Export Facilities:

With ITEM ToolKit ‘s user-defined, powerful import and export facility, you can easily transfer any or all project information to your analysis. Data can move seamlessly to and from Bills of Materials (BOM), Excel, Access, text, and comma delimited file formats. You can also create and save Import and Export templates for repeated use. The result is an incomparable time saving over manual data entry.

Hierarchy Diagrams:

Users can interactively construct hierarchy diagrams that represent the structure of a system at various levels. As new components are added to the system, each module automatically calculates and updates all dependent and overall system results.

Fully Customizable Reports

Choose from a variety of pre-formatted standard reports or design your own with text, diagrams, or graphs that you can preview or print directly.

- Incorporate bitmaps, company logos, and customer logos

- Specify column widths, fonts, and colors

- Modify existing reports and save as templates for future projects

- Easily generate and manipulate diagrams and graphs

Advance Transfer and Link Facility. A Great Time Saver:

Eliminate errors and save time from re entering data by transferring data from one analysis to another. Analyze your system under one type of analysis then transfer and link it to another type of analysis. This saves time from recreating the same system under another analysis and it also eliminates errors in re entering the data. For example; create and analyze a system under MIL-217 module and transfer and the same system to FMECA or Fault Tree analysis. The system hierarchy is created effortlessly and all relevant information is transferred and updated every time you change or update your MIL-217 analysis.

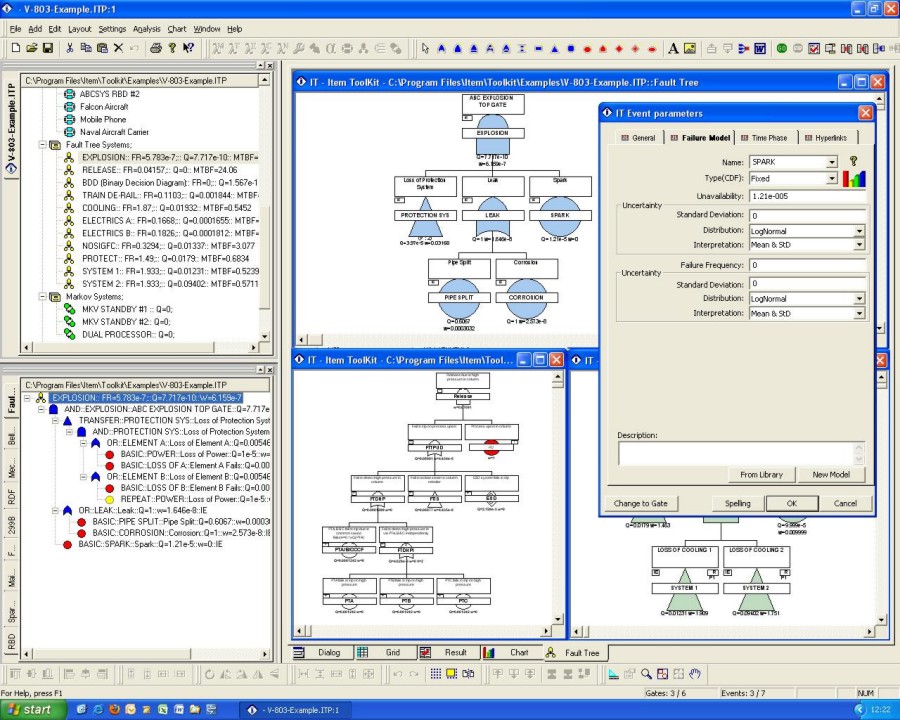

Advanced Hybrid Linking and Modeling:

ITEM ToolKit’s Hybrid Linking and modeling features allows the result of any analysis to be automatically fed into an event in a Fault Tree or a block in a Reliability Block Diagram. This feature is most useful where a simple model cannot determine the event or the failure of a block and a more complex analysis has to be performed.

Information Display Management / Sort Option:

Specify exactly what type of information is to be displayed in the project, system, library and diagram windows. View and display as much, or as little, of the detailed information such as part numbers, description, failure rate, MTBF, Unavailability, or simply your analysis results. Sort the information in numerous ways; by name, by part number, by failure rate, by contribution, by category, etc. A great tool for determining and listing items with high failure rates or low MTBF or listing items by part number, etc.

The Most Flexible and Scalable Reliability and Risk Software Application:

ITEM ToolKit offers the scalability that every user and organization has in mind. Total integration of ITEM ToolKit allows you to take advantage of one or multiple analyses at the same time. Keeping track of your product life cycle and project management are among the many benefits to such a capable application suite as ITEM ToolKit.

Features

The most flexible and scalable reliability and risk software available:

- Powerful chart and graph facilities

- Build and open multiple systems and project files

- User defined custom library facilities

- Drag and drop components and systems between projects

- Advanced hybrid linking and modeling

- Import and export data to Microsoft Excel, Access, Word, Bill of Materials, etc.

- Pre-formatted and fully customizable reports

- Information display management and sorting options

- Advanced transfer and link facilities

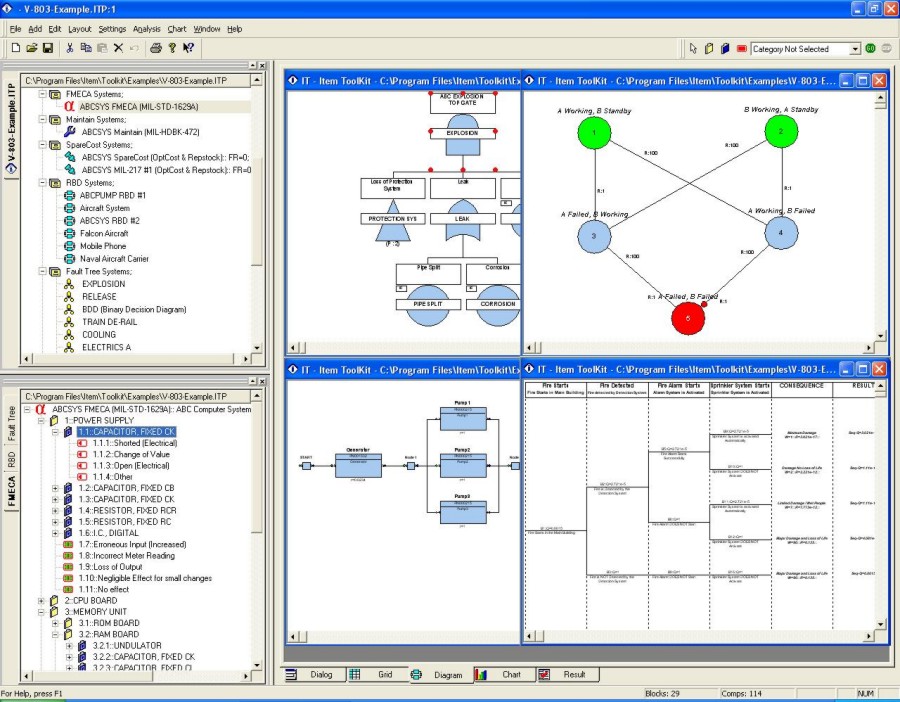

- Top-down and bottom-up Design, Process, functional, or system FMEA’s supported

- Multiple FMEA standards supported: MIL-1629A, ISO 9000, ISO 26262, IEC 61508

- Graphically constructed system hierarchy diagrams

- Automatic criticality calculations

- Redundancy modeling including hot standby

- Linked block facility reduces repetitive data entry

- 6 different Derating standards for prediction

- 4 different failure rate Allocation models for prediction

- Defense Microelectronic Activity (DMEA) support in MIL-217

- User defined connection types for MIL-217

- Cross-module Linking and Transfer

- Global failure model library between Fault Tree, RBD, and Event Tree modules

- Time phasing function in Fault Tree

- 3 different Event Importance measures

- Critical Path discovery and cut set ranking by multiple parameters

- 15 different, universally accepted failure model distributions for Fault Tree, RBD, and Event Tree

- Implicit and explicit Common Cause Failure modeling

- Dynamic modeling with Markov model linking to Fault Tree and RBD diagrams

Contact us now for a free quotation or an online demonstration.

Key Features:

- Suite of 14 Prediction and Analytical Modules

- 6 Different Reliability Prediction Modules

- Fault Tree and Event Tree Analysis Modules

- Reliability Block Diagram Analysis Module

- Failure Mode, Effects, and Criticality Analysis

- Analyze Components, Systems, and Projects

- Drag and Drop Components Between Projects

- Advanced Hybrid Linking and Modeling

- Open Multiple Systems and Project Files

- Powerful Chart and Graph Wizard

- User Defined Custom Libraries

- Fully Customizable Reports

Available Modules:

- MIL-HDBK-217 Prediction >>

- Telcordia Prediction >>

- IEC 62380 Prediction >>

- IEC 61709 Prediction >>

- NSWC Mechanical Prediction >>

- Siemens SN-29500 Prediction >>

- China 299B Prediction >>

- Failure Mode, Effects, and Criticality Analysis >>

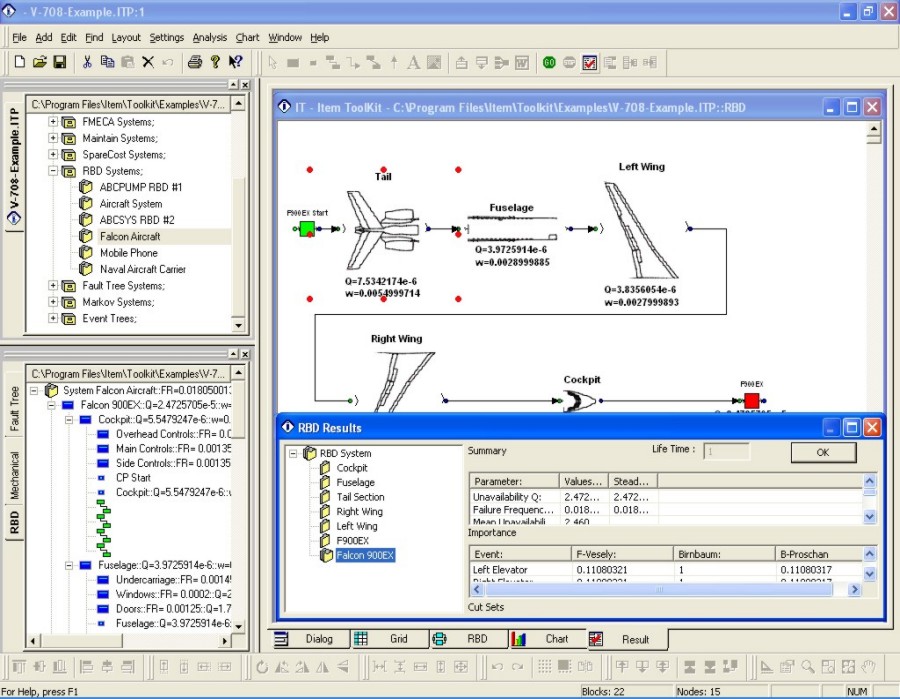

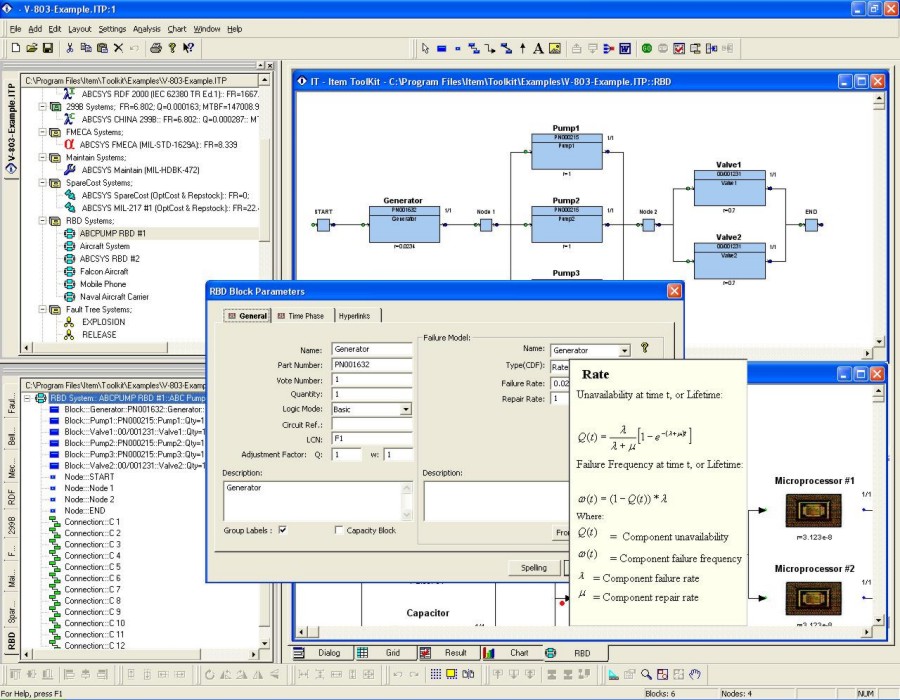

- Reliability Block Diagram >>

- Fault Tree Analysis >>

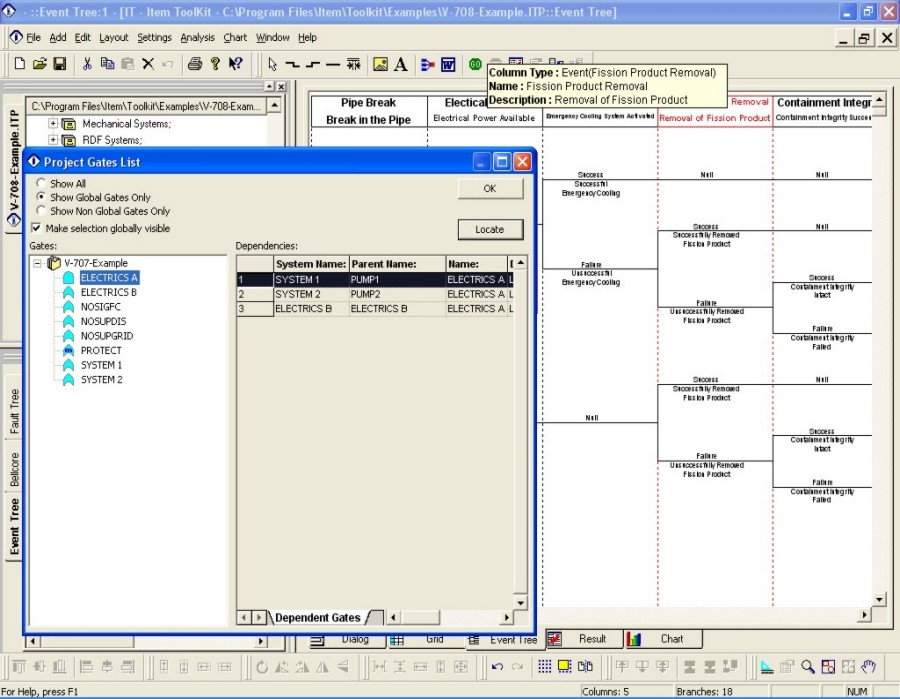

- Event Tree Analysis >>

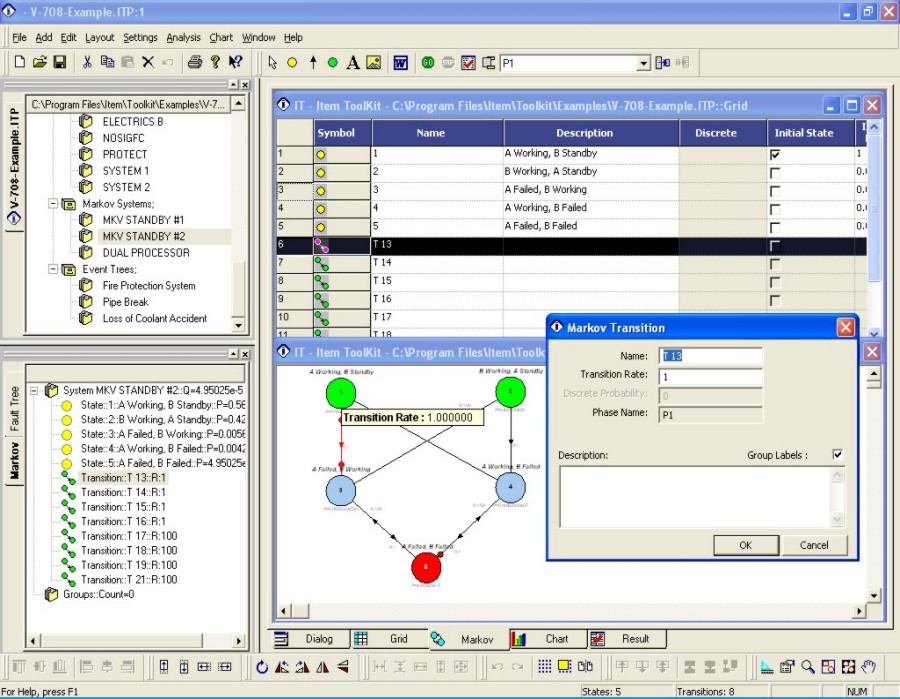

- Markov Analysis >>

- Maintainability >>

- Spares Scaling & Ranging >>